Featured Products

-

4x Ferrari F430 Coupe Carbon engine compartment cover trim

Vendor:AutoVM CompositesRegular price CHF 2,186.00Regular priceUnit price / per -

4x Ferrari F430 Spider Carbon engine compartment cover fairing

Vendor:AutoVM CompositesRegular price CHF 1,900.00Regular priceUnit price / per -

BMW E39 E46 M5 M3 3er 5er full carbon steering wheel clasp including clips

Vendor:AutoVM CompositesRegular price CHF 210.00Regular priceUnit price / per -

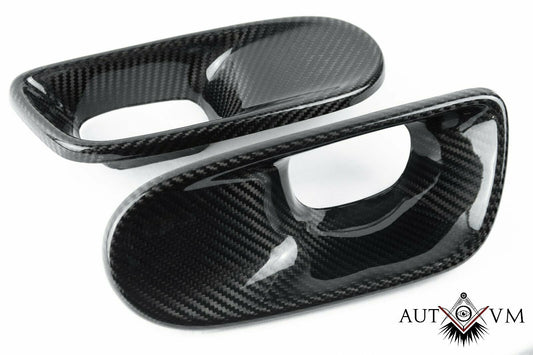

BMW E46 carbon fog lights covers air intake Airintake M package 2

Vendor:AutoVM CompositesRegular price CHF 191.00Regular priceUnit price / per -

BMW E46 M3 Coupe Sedan Carbon Interior Trim Strips

Vendor:AutoVM CompositesRegular price From CHF 514.00Regular priceUnit price / per -

BMW M5 / 5 Series E39 carbon interior trim strips set

Vendor:AutoVM CompositesRegular price CHF 946.00Regular priceUnit price / per -

Ducati 1098 1198 848 748 916 999 996 S sprocket cover real carbon for various models

Vendor:AutoVM CompositesRegular price CHF 92.00Regular priceUnit price / per -

Ducati 1098 848 1198 carbon heel pads left & right

Vendor:AutoVM CompositesRegular price CHF 43.00Regular priceUnit price / per -

Ducati 1098 848 916 996 999 carbon clutch cover

Vendor:AutoVM CompositesRegular price CHF 95.00Regular priceUnit price / per -

Ducati 1098 848 916 996 999 carbon clutch cover open

Vendor:AutoVM CompositesRegular price CHF 95.00Regular priceUnit price / per

-

Our services

- Prototype construction for small series

-Construction & development of models

-CNC milling & turning

-Mouldmaking

-3D Scanning & Reverse Engineering

-3D printing

-Painting / Coating

-

Our materials

- Carbon fiber (CFRP / “Carbon”)

- Aramid fiber (Kevlar)

- glass fiber (GRP)

- Hybrid materials such as carbon fiber & aramid

-

Our industries

- automotive industry

- racing

- aviation

- medical technology

- Sports and leisure industry

- Custom made

autoclave

Perfect carbon parts thanks to the latest technology. We rely on ours

self-developed autoclave and the use of

prepreg materials. With high pressure and temperature, the components are precisely formed and perfectly hardened. A technology that is also used in Formula 1 and sets us apart from other companies.

lamination process

Thanks to our use of "Prepreg Carbon" and precisely fitting molds, we can guarantee you an excellent result. Extreme precision is required during the lamination process, otherwise the finished part will have to be discarded. This process is characterized in particular by the precise number and alignment of the individual carbon layers.

Finish & painting

The final and most important stage of production is the final assembly.

Here every flaw in the carbon is checked and repaired to

to achieve perfect result. Each part is customized to the highest standards

Level processed and prepared for painting. We also fulfill

gladly individual customer requests.